interview

Every stage has its own needs

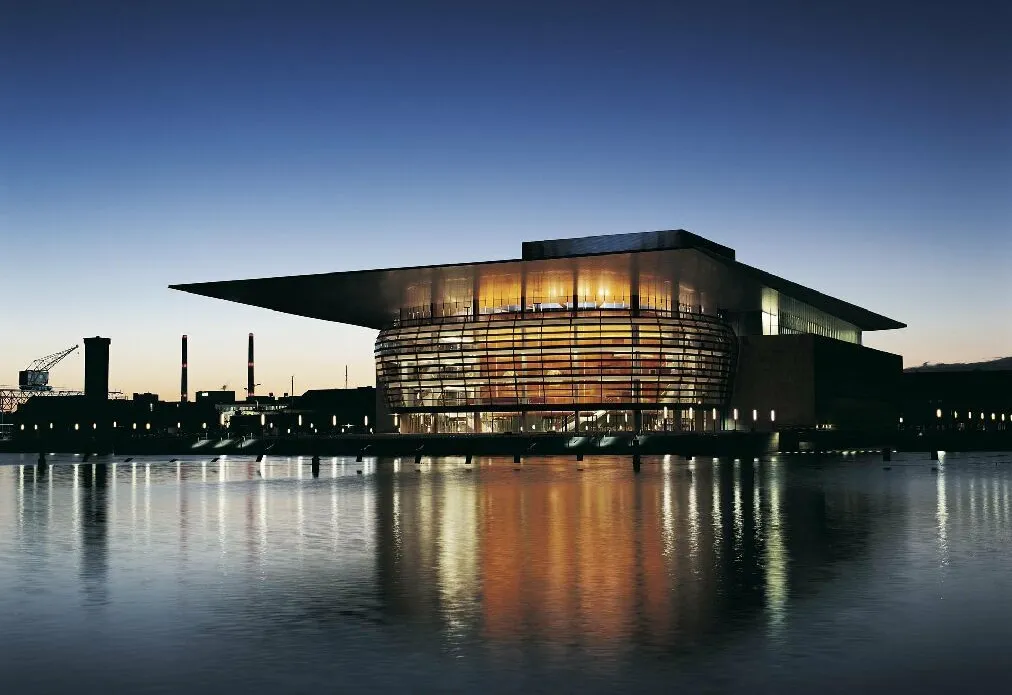

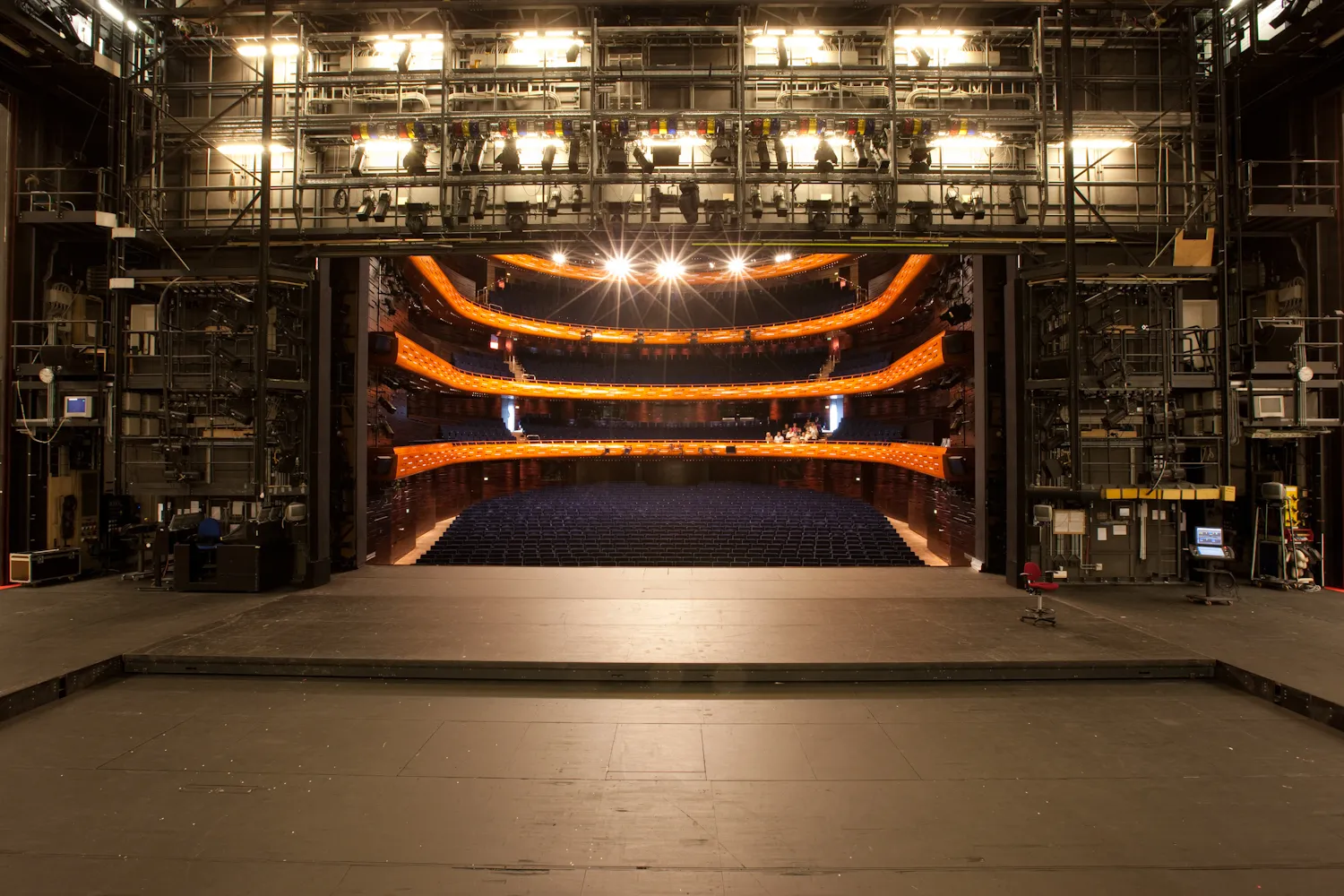

The Copenhagen Opera offers 1,500 visitiors an impressive sight and has seamlessly joined the ranks of the most important opera houses in Europe. The stage area is approx. 2,500m² with a depth of 44 m and a width of 56 m.

Reading time: 4 min 48 sec

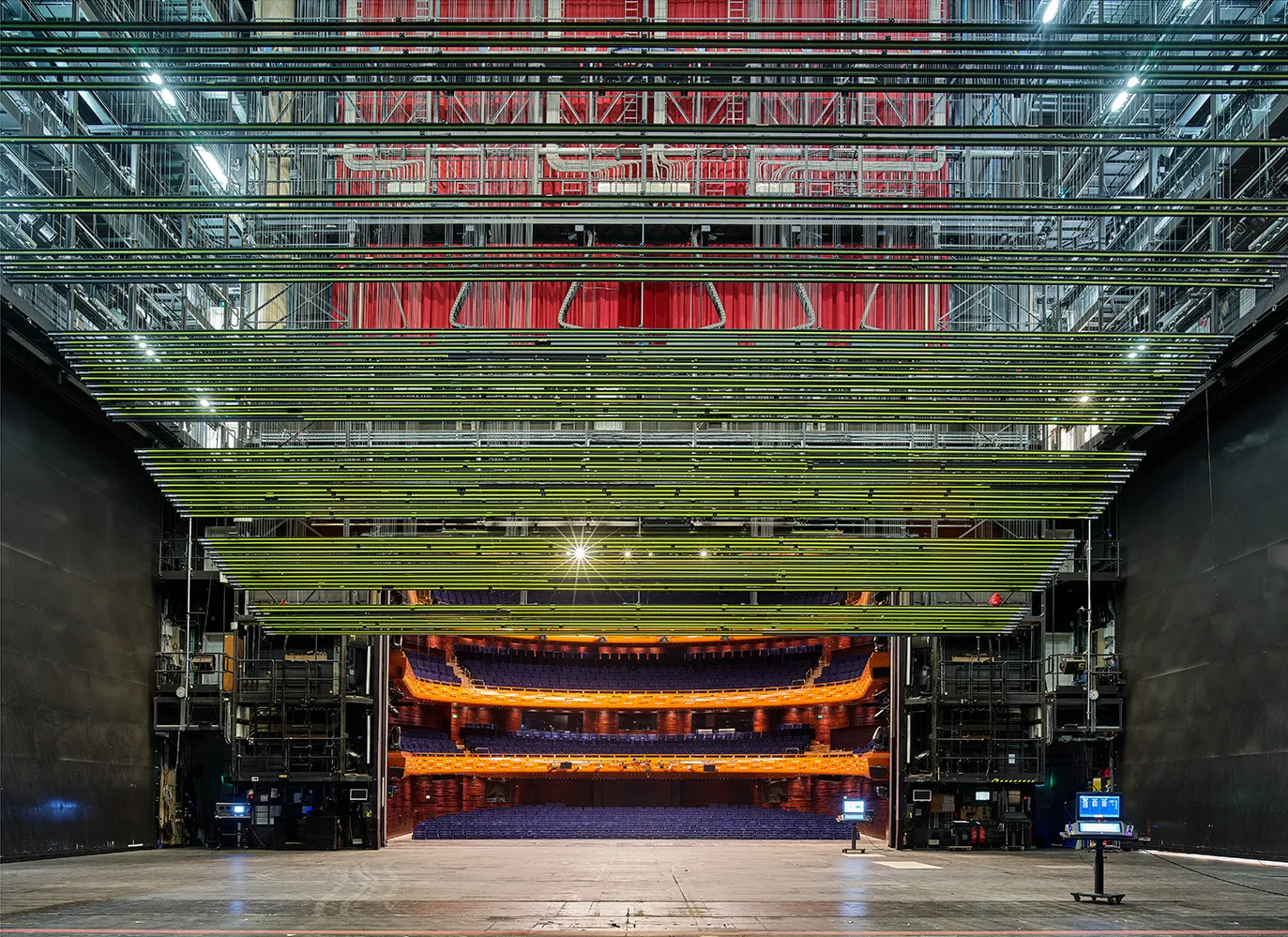

In this house a stage wagon system with so-called pinion drives was installed for the first time, which enables a small team of 10 people to easily move large and heavy decorations on and off stage. The whole stage machinery consists of 182 drives in the upper stage machinery, 108 drives in the lower stage machinery and 232 within the stage wagon system. All controlled by the C⋅A⋅T V5 control system.

An operator gives us insights how it is to work with this stage wagon systems and the latest generation of the control system compared to the former one.

Rolf Poret, Operator, The Copenhagen Opera House

I came to this house completely naked – there was nothing in it and started building up. We were fortunate that it was Waagner-Biro Stage Systems and Theatreplan who was doing all this.

The opera is one of the most modern installations that we have because it’s really from the beginning thought for being efficient. So here it’s a very small team of 10 people that do all the things together. This is mainly enabled by the stage wagon system which allows you to put a full decoration on stage but later on remove it again but leave it assembled as far as possible.

We have got 13 wagons and each wagon is 16 times 4 meter and weighs about 16 tons each. On top of that you could put 32 tons of decoration up to 10 meters high. So you can actually by just moving the joystick move 208 tons which is mind-blowing.

I’ve been on the old stage we didn’t have the wagon system. Decorations are getting heavier and heavier and what would happen if we didn’t have the wagon system would be that everything would be mounted on wheels.

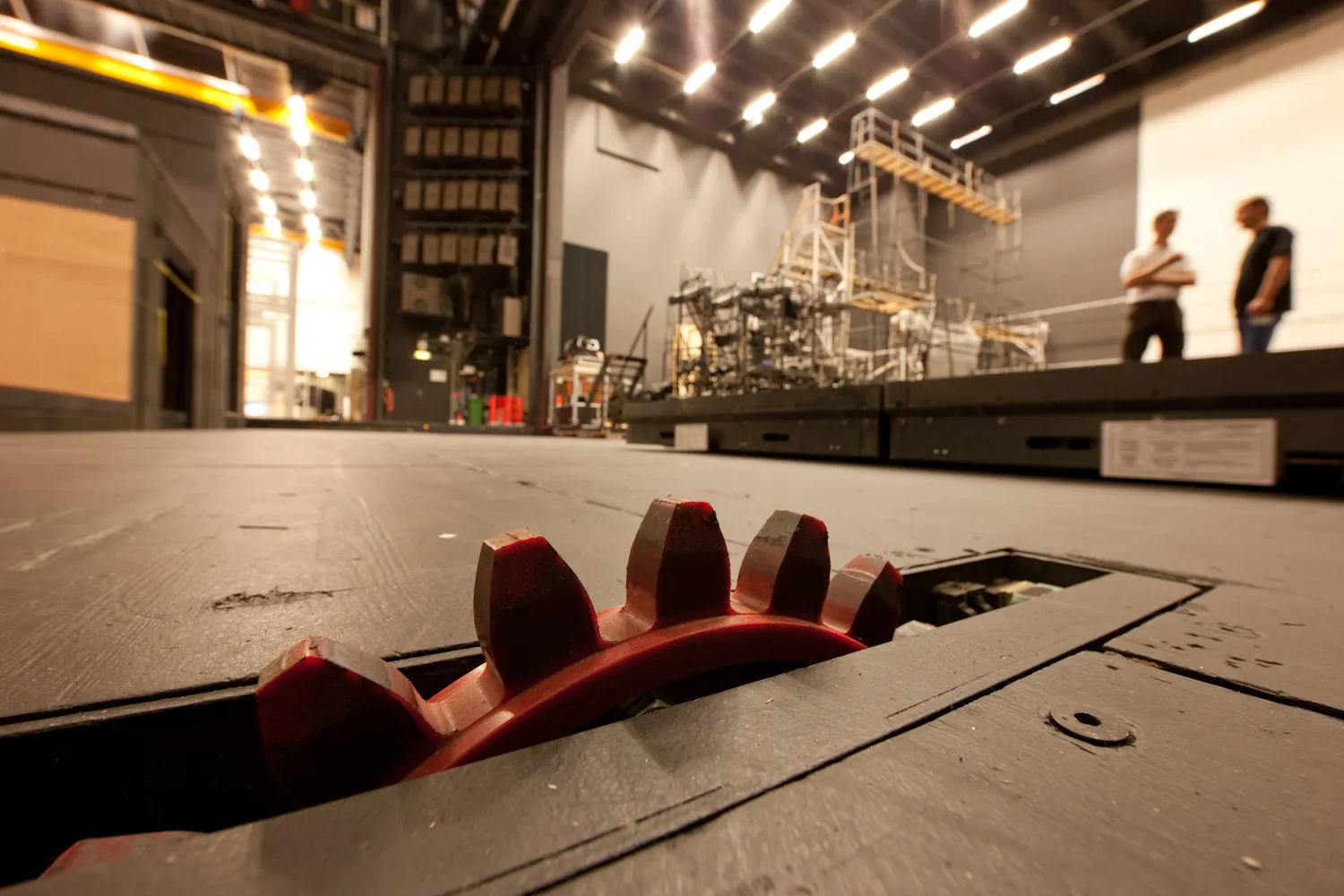

The wagon system is actually a dummy system. Inside the wagon there is no electronics. All the drives that we’re using it’s a pinion system. And it’s mounted on a motor and a gearbox and they’ve got an actuator.

Oliver Brück, Waagner-Biro Stage Systems

What you do is to rise one of 116 pinion drives from the stage floor, so these pinions are rising up and start turning and pushing the wagons to the position where they need to be. In the background there’s a lot of things that need to go on at the same time.

So there’s equaliser lifts that need to be lowered there’s the right set of pinions that need to be addressed for taking over the wagon while it’s moving.

Picture left: Pinion Drive System / Foto rechts: Stage Wagon System

Rolf Poret

It’s fairly a complicated system. That’s a lot of stuff going on once we drive it because it’s actually calculating how the pinion stands compared to where the wagon is.

Oliver Brück

For the operator it’s just one drag and drop move but what has to be done in the back it’s easily like 20, 25, 30 machines that need to be selected with the correct target positions activated and run the correct order and all this actually is done by the control system.

So it prepares all the details necessary for the wagon move but hides all the details from the operator.

So the biggest benefit of having a modern control system like the C⋅A⋅T V5 and that’s also something where C⋅A⋅T V5 is very unique is that it lets the operator focus on what they want to do and not on the way how to do it.

Rolf Poret

It’s very, very easy to use, especially because you’ve got this huge touchscreen where you can use it it’s like a giant iPad.

Oliver Brück

The design of the interface and also how it looks for us relates also to the atmosphere: If you enjoy working on a system, if you really like what you’re doing it reduces stress and for us that’s also a very important part. So the ergonomics of the system in working with it, the user experience is the key result that we want to achieve.

For every user, of course, there’s a lot of possibilities to customize the experience for themselves.

C⋅A⋅T V5 let’s you do things in your way it just checks what you’re doing and highlights if there are some conflicts and of course gives you hints and helps to solve these issues later on.

But of course for each venue it’s also possible to customize the layout of the screen so each installation gets a very bespoke custom interface of the C⋅A⋅T VIEW or machinery view screen that is unique for the venue.

Rolf Poret

We’re probably one of the biggest houses in the world, we have so many drives. We’ve got different kinds of layout for the upper machinery, lower machinery, revolve, orchestra pit, stage wagon overview of the entire stage. Each house is unique.

Foto links: Winchroom / Foto rechts: Flybars in the upper stage

Oliver Brück

An opera house has a different program has a different complexity compared to a drama theatre. A concert hall, of course, is more about setting up things and setting up a large amount of machinery within a short time.

A musical theater has very complex actions going on, often a lot of things going on concurrently, but they only rehearse it one summer and then they play the whole thing for a couple of years. So every venue has a different philosophy and different needs of how you best work with the system and that’ also what we implement in the C⋅A⋅T V5 user interface so that it really is open to all these kind of different needs and different persons that are working with the system.

Rolf Poret

I mean it can do everything.

The Copenhagen Opera House by Waagner-Biro Stage Systems

©Waagner-Biro Stage Systems

©Waagner-Biro Stage SystemsInes Schwabl

Author

©Waagner-Biro Stage Systems

©Waagner-Biro Stage SystemsAngelika Albert-Knaus

Author

7/29/2024

In this article

Waagner Biro Stage Systems